The greenhouse gases (GHG) emission of production and delivery of palm oil residue pellets has been

estimated based on the following assumptions: The pellet mill with a capacity of 50.000 to 100.000 tons per year is situated next to a palm oil extraction mill supplying 1/5 (DM) of the residues (EFB + fibre + shell). The remaining residue is supplied from nearby mills at a an average distance of 20 km (local transport), the remaining feedstock is supplied from the adjacent palm oil mill For sugar cane trash the pellets mill is located adjacent to a sugar mill which supplies energy for pretreatment and pellet making using biomass residue. The trash is supplied from nearby mills at a an average distance of 20 km (local transport), The palm mill residues are pretreated to upgrade the quality. Pretreatment involves size reduction followed by countercurrent washing with water. The water containing nutrients is then recycled for use in the plantation system. This is followed by the extraction with removing 70% of K, 50% of P and 20% of N. To calculate the loss of nutrients we use the contents as given in Elbersen et al (2013). For sugar cane trash we assume that the dry yellow leaves which have a lower nutrient content, are used.

The energy (electricity and heat) for pre-treatment, drying and pelleting is supplied by the boiler of the adjacent pellet or sugar mill burning residues. We assume that there is a financial cost, but no relevant GHG emissions of drying and electricity production. No specific GHG emissions for truck transport were identified we therefore used average numbers from different sources. The GHG emission of local transport of residues is assumed to be double that of long distance truck transport due to higher moisture content and lower efficiency due to smaller scale.

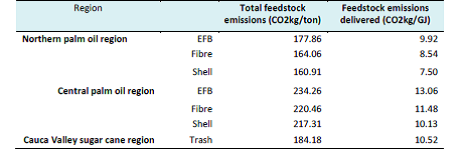

GHG emissions for palm oil residue pellets and sugar cane trash pellets delivered to Rotterdam.